Laser Engraving

What is a CO2 Laser

A CO2 laser, also known as a carbon dioxide laser, is a type of gas laser that uses carbon dioxide gas as the active medium to generate a laser beam. It operates based on the principle of stimulated emission of radiation.

CO2 lasers produce a laser beam in the mid-infrared wavelength range, typically around 10.6 micrometers. This wavelength is well-suited for various applications, including cutting, engraving, marking, welding, and surface treatment of materials like metals, plastics, glass, wood, and more.

The main components of a CO2 laser system include:

- CO2 Laser Tube: The CO2 laser tube contains a mixture of carbon dioxide, nitrogen, and helium gases. When an electrical discharge is applied to the gas mixture, it excites the CO2 molecules, causing them to emit photons and generate the laser beam.

- Optics: The laser beam generated in the CO2 laser tube is directed and shaped by a series of optical components. These components, such as mirrors and lenses, control the beam’s focus, intensity, and alignment to suit the specific application requirements.

- Power Supply: The power supply provides the electrical energy needed to excite the gas mixture in the CO2 laser tube. It typically consists of high-voltage transformers, capacitors, and other electronic components.

- Cooling System: CO2 lasers generate heat during operation, so a cooling system is necessary to maintain the optimal temperature for the laser tube’s efficient operation. Water-cooling is commonly used, where a flow of water circulates through the laser tube to dissipate heat.

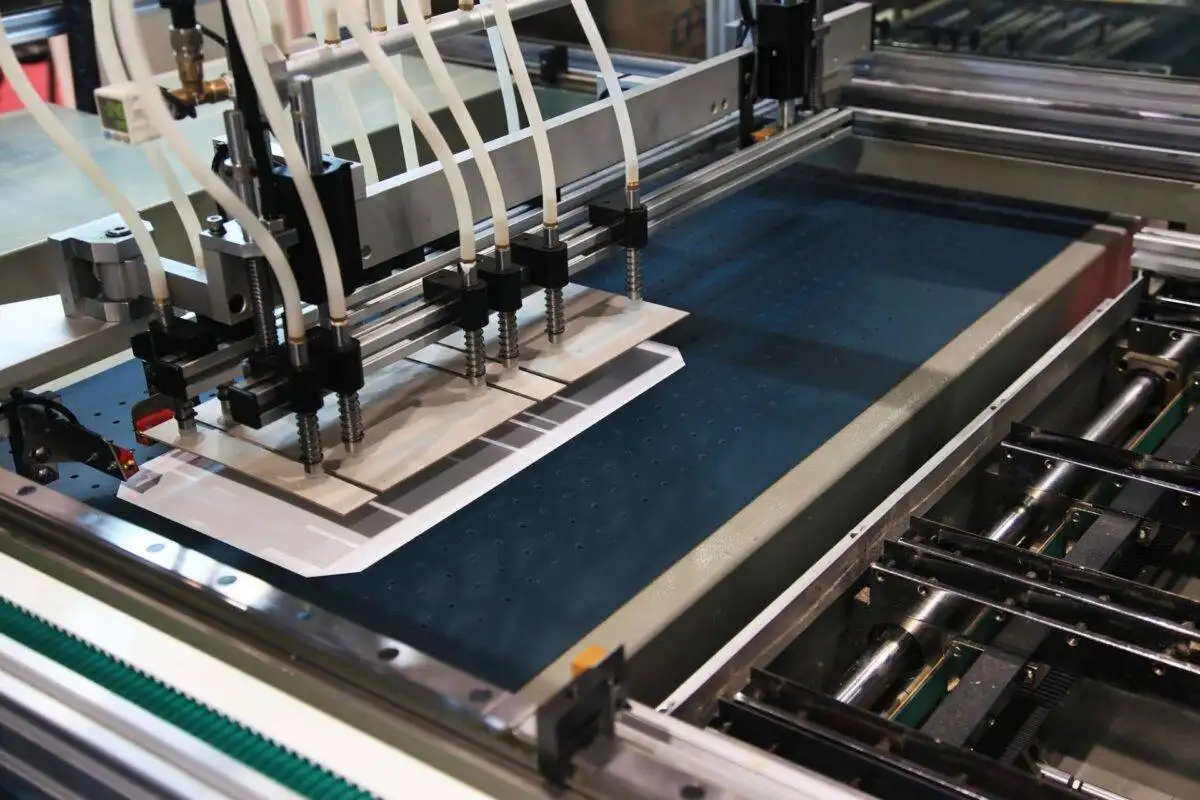

- CO2 lasers are popular in industrial and commercial settings due to their versatility and power. They are widely used for laser cutting and engraving applications, providing precise and high-quality results. CO2 lasers can cut through a variety of materials with different thicknesses, offering great flexibility for a range of industries, including signage, woodworking, automotive, electronics, and more.

- The power output of CO2 lasers can vary, ranging from a few watts for small-scale applications to several kilowatts for industrial systems. The choice of CO2 laser power depends on the specific application requirements, material types, and desired cutting or engraving speeds.

Overall, CO2 lasers are valued for their ability to deliver high-precision, non-contact processing on a wide range of materials, making them an essential tool in many manufacturing, fabrication, and artistic processes.